The Compact Cyclone Multiphase Meters are real-time measuring systems for oil, gas, and water flowing from production wells. They are used both onshore and offshore for fast, accurate, and reliable well testing. Multiphase flow meters, sometimes referred to as MPFM, are used in place of traditional two phase and three phase test separators.

CCM Systems with vessel diameters from 12 to 52 inches have been delivered to cover an entire range of production from small oil wells to large gas wells. The CCM family is engineered by Phase Dynamics to meet the specific requirements for production and test separator applications. Since it is a separation system with real gas demisters it can handle wet gas measurements.

CCM Meter

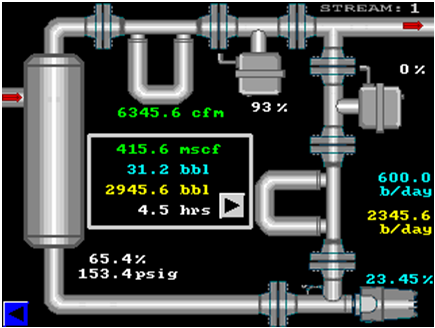

The CCM Meter is a technologically advanced way to efficiently separate gas from liquids and then accurately measure the amount of gas, oil, and water flowing before recombining the streams to the output flange. Efficient separation takes place through an advanced vessel design where tangential velocity typically creates a separation force in excess of 50 g’s. The separated gas then passes through demisting elements to further dry the gas before it is routed to the gas meter. The separated liquids are then routed for liquid metering.

Phase Dynamics utilizes the highest quality components for the CCM Meter such as FlowServe and Bettis valves and actuators, and Micro Motion Coriolis meters. Water-in-oil is metered with a Full Range Phase Dynamics Water-Cut Analyzer equipped with the Heuristic Salinity© routine.

The system measures total oil, water, and gas, pressure, temperature, and other parameters available on display or through the data interface.

Process Graphic

The Phase Dynamics CCM Meters are field proven systems for fast and accurate production well measurement.

The CCM Meters are full range measuring systems. Each system’s components are selected based on the actual flow rates and operational specifications to maximize performance and accuracy.

| Parameter | Range | Uncertainty (2σ) | Meter Type |

|---|---|---|---|

| Water-Cut | 0-100% | +/-5% | Phase Dynamics |

| Gas flow | 0-100% | +/-5% | Coriolis |

| Liquid flow | – | +/-5% | Coriolis |

This family of Analyzers is available with the following certifications:

In addition to the certifications, several additional reports are available.

The Measurement Section include coriolis flowmeters and a water cut analyzer. Process temperature capabilities are 0 to 160ºC.

The Electronics Enclosure Section contains the majority of the electronics with displays and user I/O. Ambient temperature capability is -40ºC to +60ºC.

The Measurement Section is available in many custom configurations. Inlet and outlet pipe dimensions from 3 to 16 inches and vessel diameters from 12 to 52 inches are available. Wetted materials are typically 316/316L Stainless steel.

The Electronics Enclosure is available in explosion proof models made from either stainless steel or aluminum.

The display is a 6-inch color touchscreen with a data logging feature. Graphing functions are provided to present trend data in an intuitive easily discernable format. The enclosures provide for user interaction through a 4-button interface in addition to the touchscreen.

The display is a 6-inch color touchscreen with a data logging feature. Graphing functions are provided to present trend data in an intuitive easily discernable format. The enclosures provide for user interaction through a 4-button interface in addition to the touchscreen.

Touchscreen Display

System power is supplied through either 100 to 240 Vac or 24 Vdc. Typical power dissipation is 20 Watts, maximum power dissipation is 34 Watts.

The data interface includes MODBUS, HART, analog I/O, pulse input, and alarm relays.

Instrument air for pneumatic valves, 20-100 PSI.

Price quotations for the CCM are based on the information provided in the Application Submission Sheet

– Please fill-in this form and email to [email protected]