Introduction

Phase Dynamics Water-Cut Analyzers are precision real-time instruments developed specifically for use in the oil industry to measure the amount of water in oil for the petroleum industry. The Analyzers, also referred to as BS&W meters or basic sediment and water meters, are used in many applications including fiscal transfer, production monitoring, and well testing. The product line is based on the innovative sensing technology of oscillator load-pull. As the mixture of flowing liquids passes through the measurement section, the oscillator senses the entire cross section of the material and instantaneously shifts in frequency as the material composition changes. This frequency shift is a direct measure of material changes within the measurement section. From a sensor technology perspective alone, Phase Dynamics sets the standard.

For three decades, Phase Dynamics has supplied this product family globally to the top names in the oil industry. It is selected for many reasons including quality, reputation, repeatability, and stability. In addition, each analyzer manufactured by Phase Dynamics is factory calibrated, tested, and inspected under rigorous standards. Electronic components receive factory burn-in cycles to further improve quality and service life. Thorough documentation practices make each analyzer fully traceable for future reference.

Enclosure & Measurement Sections

The product family is highly customizable to meet the exact needs of the global market. Each Analyzer consists of a Measurement Section, an Electronics Enclosure Section, and an interconnecting system cable.

Measuring Range

Analyzers are available in six measurement range options to fit the application. For example, the Low Range Analyzer is typically used for custody transfer or pipeline applications whereas the Full Range is used for well testing and production applications where high water cut is present. The oscillators for each measurement range have been optimized to provide maximum load-pull to achieve best-in-class precision and repeatability.

Measurement uncertainty is expressed as the 95% confidence interval or two standard deviations. Oø denotes the water-in-oil emulsion phase, Wø denotes oil-in-water emulsion phase. Inversion refers to the emulsion phase change from water-in-oil to oil-in-water. The Full and High Range Analyzers offer Heuristic Salinity© as a product option to maximize measurement performance in applications where salinity change is also a process variable.

|

Parameter

|

Low Range

|

Mid Range

|

Full Range

|

High Range

|

||

|

Measuring Range

|

0-4%

|

0-10%

|

0-20%

|

0%-Inversion

|

0-100%

|

80-100%

|

|

Uncertainty (2σ)

|

+/-0.04%

|

+/-0.04%, 0-4%

+/-0.1%, 4-10%

|

+/-0.04%, 0-4%

+/-0.1%, 4-10%

+/-0.2%, 10-20%

|

+/-0.5%

|

+/-0.5% Oø

+/-1% Wø |

+/-0.6% Wø

|

|

Repeatability

|

+/-0.02%

|

+/-0.02%

|

+/-0.1%

|

+/-0.1%

|

+/-0.1% Oø

+/-0.5% Wø |

+/-0.3% Wø

|

|

Resolution

|

0.01%

|

0.01%

|

0.1%

|

0.1%

|

0.1%

|

0.1%

|

Certifications

This family of Analyzers are available with the following certifications.

- CSA: Class1, Division 1, Groups C and D; Class1, Zone 1, Group IIB

- FM: Class 1, Division 1, Groups C and D

- ATEX: EEx d IIB T5, CE Ex II 2 GD, IP66

- PED: Module A1

Reports

In addition to the certifications, several additional reports are available.

- PMI - Positive Material Identification

- NDE / NDT - Non Destructive Examination / Testing

Workmanship Standards

Workmanship and material standards include these items:

- ASME B 16.5

- ASME B 31.3

- ASME Section IX

- EN 10204

- NACE Standard MR0175/ISO15156

- ISO9001:2015

Temperature

The Measurement Section is the portion of the Analyzer that contains the sensing elements where fluids are flowing at process conditions. Process temperature capabilities are 0 to 315ºC.

The Electronics Enclosure Section contains the majority of the electronics with displays and user I/O. Ambient temperature capability is -40ºC to +60ºC.

Measurement Section

The Measurement Section is available in four flow configurations. Three are flow-through types configured as "L", "U", and "Z" shapes, and one is an insertion type. For the flow-through types, the available diameters are 1, 2, 3, and 4 inches while the insertion type is available in 3 inch only. The insertion type is intended for installation in pipes that are 6 inches in diameter and larger. Flow rates of 2 feet per second to 14 feet per second are recommended to assure the best measurement.

The standard material is dual grade 316/316L stainless steel with Cr-22 Duplex and C-276 Hastelloy as available options. Norsok M-630/M-650 compliant materials are available for the wetted parts. Process connections are through ANSI Class 150#, 300#, 600#, 900#, and 1500# flanges. Process temperature is monitored with a built-in RTD sensor.

Electronics Enclosure Section

The Electronics Enclosures are available in explosion proof models made from either stainless steel or aluminum and a weather tight fiberglass model.

There are two display options, a 6-inch color touchscreen or a 4-line x 20-character LCD.

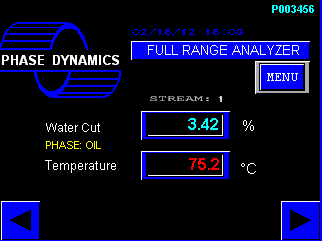

Touchscreen Display

The touchscreen display provides the user with a convenient touch-based navigation system. This display option includes the data logging function. In addition, graphing functions are provided that present trend data in an easily discernable format. For Full Range and High Range Analyzers, the recommended Heuristic Salinity© option requires the touchscreen display.

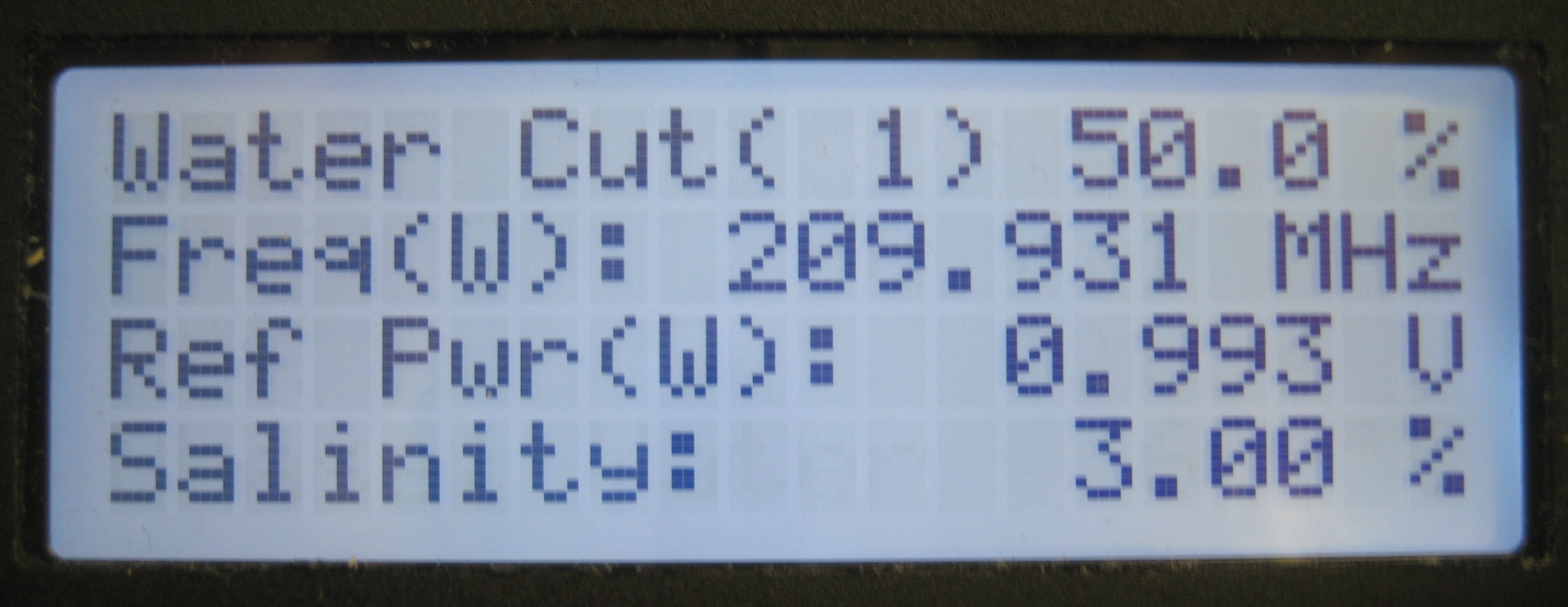

LCD Display

The explosion proof enclosures provide for user interaction through a 4-button interface in addition to the display selected. The Fiberglass enclosures are configured in two ways. When the touchscreen is purchased, user interaction is through the display. When the 4-line LCD is purchased, user interaction is accomplished through a 4-button interface.

System power is supplied through either 100 to 240 Vac or 24 Vdc. Typical power dissipation is 18 Watts, maximum power dissipation is 33 Watts.

The data interface includes MODBUS, HART, analog I/O, pulse input, and alarm relays.

The Enhanced Electronics package option includes:

- 4 x MODBUS RTU

- 1 x HART (opt.)

- 1 x 4-20mA input

- 1 x 4-20mA output

- 1 x pulse input

- 2 x alarm relays, 1A / 125Vac

The Expanded Electronics package option includes:

- 4 x MODBUS RTU

- 1 x HART (opt.)

- 5 x 4-20mA input

- 5 x 4-20mA output

- 3 x pulse input

- 2 x alarm relays, 1A / 125Vac

Flow Computer functions are provided with the inclusion of fluid flow as an input to the Analyzer. Net Oil and Net Water results are then available for display and output through the data interface ports.

System Cable

A multiconductor system cable connects the Measurement Section to the Electronics Enclosure Section. Standard lengths are available from 30 to 150 feet.

Documents

Product Video

Request for Price Quotation

Price quotations are based on the model number. Please define the model number using the Model Number Coding guide or fill-in the Application Submission Sheet. Email either or both to This email address is being protected from spambots. You need JavaScript enabled to view it.

- Model Number Coding - Defines an exact product configuration for quotation.

- Application Submission Sheet - Please fill-in this form and email to us.